Updated 21 August, 2001

|

The Mill Here's the single largest investment I've made in my home workshop -- it cost me around NZ$2,000 (US$1,000) for the mill -- and then I spent about as much again on tooling, vices, a clamping set, rotary table, etc. It's a Rong Fu model 30 drill mill which I bought on the recommendation of the kind folks in the rec.crafts.metalworking newsgroup. Actually they said "buy a bridgeport knee mill" until I pointed out that I wasn't made of money. I just love having a mill! With a mill, lathe, MIG and oxy-torch now I'm sure I can build just about anything my mind cares to imagine -- oh the power :-) |

|

|

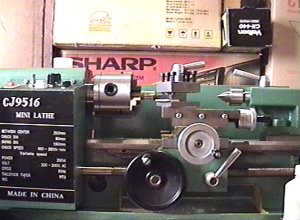

The Lathe Yes, I'm afraid it's one of those cheap Chinese lathes. Although at first glance it looks just like the Harbor Freight ones, it does a few small differences and came with some nice extras. I'm very pleased that it came with a really comprehensive set of metal gears for the lead-screw drive -- this has meant I've been able to turn a lot of threads for which I didn't have dies. However, I have made a modification to the compound in order to fix a nagging problem and I've recently built my own Quick-change toolpost. If you have, or are thinking of buying one of these great little lathes then you really ought to visit Frank Hoose's Minilathe Site -- it's a goldmine of information. |

|

The Drill Here's another piece of oriental machinery. When I first assembled it it had more than an acceptable amount of run-out but after playing around and trying a whole lot of different arbor/chuck alignment combinations (ie: mount the chuck, measure run-out, unmount, rotate 5 degrees, try again), I finally got it down to an acceptable amount. It was only US$150 so I guess I can't complain -- and for "precision" drilling I can always use the mill. |

|

The MIG Welder

The MIG WelderMade in Italy -- that's what it says on the front -- and it's not a bad little spark-box. Within about half an hour of using it, I rapidly gave up on using the tiny disposable gas bottles that this unit was designed to use and bought a couple of F-size bottles and a regulator. Don't fall into the trap of believing that you'll be able to survive with those little bottles -- they only last about 8 minutes each unless you're using pure CO2 -- which lasts about 20 minutes. Now, thanks to the switch to F-sized bottles, I have almost unlimited (for a HSM) stream of argon/CO2 (for steel) and pure argon (for aluminum). Just a note ... before I bought this welder I used to pay the bodywork shop down the road to weld up the handle on my lawn-mower (which was always breaking where the mounting bolt goes through). Their MIG welds would last about 3 months before breaking again. Using this box I welded up the same break over 9 months ago and it's still holding strong -- plus it looks soooooo good :-) |

|

The Dremel The Dremel is such an incredibly useful little tool that I just had to include it here. It grinds, it sands, it mills, it drills, it cuts, it polishes, it engraves, and best of all it makes a really cool whirring noise ;-) Most recently I've found that when fitted with a medium-sized steel burr it's extremely useful for preparing aluminum surfaces prior to MIG welding. A couple of quick passes and you've exposed some clean metal and are ready to weld. If you mess up you can also cut back some of those awful beads and start again ;-) As a model builder I find doing anything without my Dremel would be somewhat akin to running a marathon with just one shoe on -- it could be done but it would be much less fun. |

|

My Gas Welding Gear

My Gas Welding GearNow that I've got my gas welding gear I don't know how I managed without it before. Maybe if I had a TIG I wouldn't need both the MIG and the gas set but I often find myself using gas to do important welds -- simply because it seems to offer more flexibility in terms of the process and the types of material that can easily be joined. If you try hard enough you can braze just about anything to anything -- just try joining copper to steel with a MIG! Also, until I get a plasma cutter, gas is the only practical way to cut reasonably thick lumps of steel -- especially if there are curves involved. |

|

The Compressor Again, I asked the guys on rec.crafts.metalworking whether it was worth forking out for a compressor -- and they said yes -- so I did. I'm glad to say that it was a great investment and I use it a lot more than I thought I would. It's only a budget-sized direct-drive unit rated at 8cfm (and I think that's a pretty optimistic rating at that) but it does what I want. The worst aspect is the incredibly loud and irritating noise it makes when it's running -- it almost scares the crap out of you when it starts up if you're not expecting it. |

|

Electronic Gear

Electronic GearHaving spent the first 15 years of my working life as an electronics engineer I find myself still dabbling from time to time. Certainly my gas turbine engine has more than its fair share of electronic subsystems so having the right gear was deemed essential. I manage to get by with a dual-trace CRO and a digital multi-meter along with a well stocked array of resistors, capacitors, semis and other odds and ends. One day I'll build a CNC adaptor for my lathe and mill (yeah -- maybe). |

|