Bringing the pulsejet engine into the 21st century

Last Updated: 21 May, 2002

|

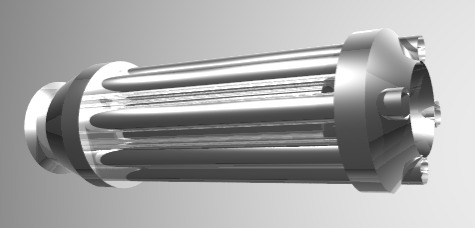

New Configuration (21 May 2002) I have revised the design of the proposed 3rd prototype X-Jet engine and those revisions have been incorporated into the image above. The changes come as a result of now being able to reliably trigger a high magnitude combustion (HMC) without the need for any valving to produce post-ignition confinement. Yes, the X-Jet has become a valveless engine that, unlike any other valveless pulsejet I've ever seen, sucks air in at the front and ejects its exhaust from the rear -- thus allowing it to benefit from the type of ram-induction effect that boosts the performance of valved engines at speeds of up to about 400 mph. Unlike the previous 3rd prototype design, this revised version would require no moving parts and will be self-sustaining without the need for externally powered and timed ignition. The form factor of this engine is also much closer to that of a turbojet, perhaps making it an easy swap-in replacement for some applications.

Latest Development News (6 May 2002) Here's a summary of what has been achieved since I last updated this page. The results of shrouding the original prototype produced good news and bad news. Although the measured 18% increase in static thrust was less than I'd hoped for, the airflow between the engine and the shroud significantly reduced the external operating temperature of the engine. Even static runs (on the test-stand) produced shroud temperatures of less than 200 deg C -- making it practical to mount the engine in close proximity to an airframe or other flamable material. When I originally designed the X-Jet I thought I knew why it was producing higher power levels than earlier (traditional) designs. However, after much experimentation it appears that my assumptions were incorrect and the actual mechanism responsible for the higher power levels is quite different (albeit very real).

A New Test Rig Is Born I hope to post some pictures of the rig shortly. The rig has proven that my revised understanding of the factors which have given the X-Jet its higher power and improved SFC were correct -- and allowed me to further refine their effect to produce even more impressive results. The early focus of my research and experimentation was on significantly increasing the levels of compression obtained prior to and during the initial phases of combustion -- but while trying to achieve this I have made some very interesting observations and discoveries.

What is an HMC? This new rig isn't an engine -- it's a single-pulse setup which I'm using to try and improve combustion power levels and efficiencies. During this new testing phase I have, produced combustion that appears to be a level of magnitude greater than even the most powerful deflagrations previously obtained. It was these occasional HMCs or High Magnitude Combustion that forced a switch to much stronger materials. Each time one of these HMCs occurred I was forced to rebuild the rig as the damage was substantial -- although no collateral damage or injury was sustained. Let me make it quite clear that I'm most certainly not suggesting that the HMCs I'm achieving are true detonations such as those used in a Pulse Detonation Engine (PDE). Unfortunately I don't have the equipment needed to measure the speed of the combustion flame-front so I'm currently flying blind in respect to such things. I find it extremely unlikely that I could have stumbled onto a technique for generating true detonation in an air-fuel mixture when NASA and the world's best universities appear to have yet sorted out all the problems. It is far more likely that I'm simply obtaining a very high-power deflagration, however the net effect is that if I can produce these HMCs in a running engine then the power levels and SFC of such an engine will be markedly superior to my existing X-Jet prototypes. Besides which, the method used to trigger these HMCs is significantly different to those employed by PDE researchers and involves the creation of severe pressure gradients over a very large effective area within the combustion tube combined with strong post-ignition confinement. The violent release of energy associated with these HMCs has necessitated a strengthening of the mounts used to secure the rig as the severity of just a single blast (through a 20mm tailpipe) was enough to put a 60 degree bend in the original 5mm steel mounting lugs that had previously showed no signs of distress. The noise generated by an HMC is quite different to a regular combustion -- being a very sharp (and loud!) "crack" rather than the "bang" associated with normal deflagrations. In my latest experiments I have been able to obtain these HMCs on a frequent (although not yet totally consistent) basis. HMCs excepted, I have discovered that increasing the pre/early ignition compression of the air/fuel mixture is a process that produces diminishing returns -- although it is very clear that traditional pulsejets are woefully inadequate at providing such compression. Once I've learned as much as I can from the combustion test rig, I plan to build a running engine using my findings. I am confident that I will shortly be able to reliably achieve HMCs and, if so, the power/size and SFC of the engine will be significantly improved over earlier prototypes. Unfortunately this will come at the cost of some complexity.

|

|