Jet engine technologies for interested amateurs

Last Updated: 9 April, 2001

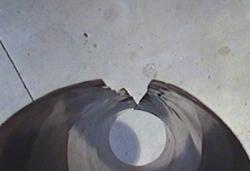

Too Much Power? The picture you see on the right is/was the tailpipe of my prototype 100lbs-thrust

pulsejet after I exceeded the designed limits of its construction.

The picture you see on the right is/was the tailpipe of my prototype 100lbs-thrust

pulsejet after I exceeded the designed limits of its construction.

This not only shows that these engines should be treated with respect, but also proves the necessity to design for "worst case" situations and create methods for "safe failure" -- as was the case here.

Background A difuser's role is to slow the incoming air and allow it to expand into the combustion zone in a controlled manner. By adding a difuser, the flow of air into the engine is greatly improved because there is less drag created as it spills through the reed-valves and into the combustion zone.

The new injector was designed to allow higher rates of fuel-flow than the previous unit so as to take advantage of the improved breathing efficiency of the modified engine and thus produce more power. Initial tests of the modified engine were very positive. The difuser did indeed improve airflow and it was apparent that the exhaust note was far sharper than before -- indicating that possibly the air/fuel charge was being compressed somewhat more effectively than before.

The extra power produced by the modified engine was very noticeable -- creating some very "kick in the pants" acceleration. After a short run up and down the road, the engine was stopped and allowed to cool so that the new thicker reed valves could be inspected for signs of wear. They seemed only slightly frayed so the decision was made to run the engine again for a longer period. Now, when starting a pulse-jet engine it's not uncommon to get a few pops and bangs before sustained combustion is achieved. This happens because the air/fuel mixture might be too rich or too lean when the spark and air is first applied. On a small engine these pops and bangs are of no consequence -- but on a larger engine they can be quite significant.

Built To Fail The biggest risk is that the normal deflagration (buring) of the fuel will become a detonation (explosion). Indeed, this is what happens when you get those very loud bangs when starting a pulsejet engine. In such cases, the deflagration of the air/fuel mixture (and resulting creation of rapidly expanding hot gases) causes the rest of the unburnt air/fuel to be significantly comrpessed -- to the point where it explodes rather than burning. This is very similar to the detonation that occurs in regular internal combustion engines when they start knocking or "pinking" under heavy load at low RPMs. This detonation is most likely to occur in a pulsejet if the entire engine is filled with a combustable air/fuel mixture and the burn starts at the end of the tailpipe. In such a case the flame front rapidly moves towards the front of the engine, comrpessing the remaining air-fuel as it goes -- because that air/fuel is traped and contained by the reed-valves. Eventually, instead of buring, the remaining air-fuel simply explodes with very significant force. When I designed and built the 100lbs-thrust engine I was acutely aware of this possibility and for that reason I built the tailpipe using a series of "stitch-welds" along the seam. These stitch welds provided a "weak-point" which would fail and release most of the explosive force before it could cause more significant damage to the engine.

The force of the detonation was so great that it buckled a steel roll-up garage door some 10 feet behind the engine and almost all the stitch-welds on the tailpipe yeilded as designed. Not only did the welds yeild but portions of the stainless steel tailpipe were quite stretched by the tensile forces involved. After tearing down the rest of the engine and closely inspecting it, no signs of cracking or excessive stress were found -- although the reeds were severely bent.

Why Did This Happen? The answer is related to the new fuel-injector. As mentioned above, this injector was designed to provide a greater fuel-flow so as to take advantage of the improved airflow that the difuser would provide. It would appear that the extra fuel flowing into the engine during the startup phase produced an explosive mixture of much greater size than had previously formed inside the engine -- with the result that the power of the detonation was similarly much larger than the engine had experienced before. Needless to say I am very happy that the engine failed as it was designed to -- this avoiding the chance of damage or injury. Repairs to the engine are very cheap and straightforward -- a new tailpipe and a new set of reed-valves. I will however be revising the start-up sequence to ensure that fuel flow is kept to a minimum prior to ignition.

|

|

In order to add the difuser I had to build a new fuel-injector so as to provide

the necessary clearances.

In order to add the difuser I had to build a new fuel-injector so as to provide

the necessary clearances.

However, this harsher combustion and increased power did mean that the

original 0.006" reed valves were destroyed in just a few minutes of operation

so a change was made to 0.012" material and another run was undertaken

with the engine mounted on the

However, this harsher combustion and increased power did mean that the

original 0.006" reed valves were destroyed in just a few minutes of operation

so a change was made to 0.012" material and another run was undertaken

with the engine mounted on the

Fortunately, this is exactly what happened when the engine detonated during

the starting attempt.

Fortunately, this is exactly what happened when the engine detonated during

the starting attempt.