Last updated 11 April, 2000

Here are some pictures of my flame-tube.

Here are some pictures of my flame-tube.

The flame tube is designed to mix a small percentage of the air that enters the combustion chamber with the fuel and control the burning process so that the flame never actually touches the walls of the chamber or extends into the turbine area. Combustion chamber and flame-tube design appears to be something of a black art and I guess I just lucked out because this was my first attempt and it seems to work very well.

The material itself seems to be standing up to the heat very well with no signs of oxidation or melting -- although it has turned a lovely shade of very deep blue from the heat after about 40 minutes of running. I figured that this metal mesh would allow air into the combustion area while keeping the flame contained -- and that seems to be the case. You'll note that I've added some extra holes as well but there are nowhere near as many holes in my unit as I've seen in many of the others on the Web.

The stainless mesh is rolled into a truncated cone and attached to the short section of steel tube by some "spot brazing" -- so that it is easy to remove if necessary. The whole assembly simply bolts onto the top of the combustion chamber using six hex-key machine screws -- I milled the mating surfaces of the flange so no gasket seems to be required. Using this flame tube I'm getting exhaust gas temperatures (EGT) of around 600 degrees Celsius at high power (20-40 PSI of boost) settings. The temperature actually rises if you throttle back to 8-10 PSI of boost -- reaching as much as 800 degrees C in such cases -- go figure!

Inside you can see the spark plug and the fuel injection tube. You can't quite see it in this view but I deliberately used small tack-welds to join the edges of the tube so as to allow some air to flow through the join into the central part. The pipe from the compressor enters the combustion chamber at a tangent such that it is forced to swirl clockwise (viewed from the exhaust end). My plan was that some of this tornado-like airflow would be "caught" by the join seam and set up a similar vortex inside the flame tube. Note the somewhat "quick and ready" construction of the tube -- my excuse is that it seems the more crudely constructed your flame holder is, the more likely it is to work properly (Murphy's law I guess).

|

|

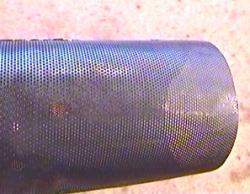

One choice I made which may have played a part in the success of this

flame-tube was the choice of materials. Instead of using a solid steel tube

like most people before me have, I chose a stainless steel mesh that I found

in the scrap bin of a local engineering workshop. Subsequently I've seen

this mesh for sale at the local metal wholesalers so I guess it's a pretty commonplace material.

One choice I made which may have played a part in the success of this

flame-tube was the choice of materials. Instead of using a solid steel tube

like most people before me have, I chose a stainless steel mesh that I found

in the scrap bin of a local engineering workshop. Subsequently I've seen

this mesh for sale at the local metal wholesalers so I guess it's a pretty commonplace material.

I designed the flame tube so that it was easily removed and could be modified

simply. The flange holds the fuel tube (just a copper pipe with flattened end)

and the sparkplug, and has a short section of pipe welded to it. This piece

of pipe forms the start of the flame tube and has four holes drilled in it

to allow some air to directly reach the injection point so as to aid ignition.

I designed the flame tube so that it was easily removed and could be modified

simply. The flange holds the fuel tube (just a copper pipe with flattened end)

and the sparkplug, and has a short section of pipe welded to it. This piece

of pipe forms the start of the flame tube and has four holes drilled in it

to allow some air to directly reach the injection point so as to aid ignition.

Here's a shot of the flame tube looking in from the open end.

Here's a shot of the flame tube looking in from the open end.